Help Center - Everything You Need to Know About Surfboards

About Greenlight

Yes. Place your order online and we'll notify you when it's ready to pick up in the from hallway of our factory. Usually within 2 days of ordering (except EPS blanks - see below)

NOTE:

WE MANUFACTURE ALL ENGINEERED EPS SURFBOARD BLANKS PER ORDER ALLOWING FOR OPTIMAL CUSTOMIZATION TO MAKE SHAPING EASIER, FASTER, AND WITH LESS DUST.

DUE TO HIGH DEMAND PLEASE ALLOW UP TO 2 WEEKS BEFORE PICK UP NOTIFICATION OR SHIPPING.

The Greenlight Pick Up Area is Open 10 am - 8 pm Daily.

Online orders only. You'll be notified when your order is ready to pick up.

NOTE:

WE MANUFACTURE ALL ENGINEERED EPS SURFBOARD BLANKS PER ORDER ALLOWING FOR OPTIMAL CUSTOMIZATION TO MAKE SHAPING EASIER, FASTER, AND WITH LESS DUST.

DUE TO HIGH DEMAND PLEASE ALLOW 3 WEEKS BEFORE PICK UP NOTIFICATION OR SHIPPING.

Online orders only, we do not have a retail store. We'll notify you via email when your order is ready to pick up.

NOTE:

WE MANUFACTURE ALL ENGINEERED EPS SURFBOARD BLANKS PER ORDER ALLOWING FOR OPTIMAL CUSTOMIZATION TO MAKE SHAPING EASIER, FASTER, AND WITH LESS DUST.

DUE TO HIGH DEMAND PLEASE ALLOW 3 WEEKS BEFORE PICK UP NOTIFICATION OR SHIPPING.

| Our pricing structure is set up to offer discount pricing to both manufacturers and individuals. You don't need a business license or tax ID # to save money when buying from Greenlight. Reduced pricing is based on quantity discounts on the following items.

|

Most pickups are available within 2 days of ordering, EPS blanks are 3 weeks... We'll notify you when it's ready

NOTE:

WE MANUFACTURE ALL ENGINEERED EPS SURFBOARD BLANKS PER ORDER ALLOWING FOR OPTIMAL CUSTOMIZATION TO MAKE SHAPING EASIER, FASTER, AND WITH LESS DUST.

DUE TO HIGH DEMAND PLEASE ALLOW 3 WEEKS BEFORE PICK UP NOTIFICATION OR SHIPPING.

Let us know what you need ASAP and we'll hold your order to include it. We will send a secure payment link for you to purchase and we'll ship it all out.

There is a $2.50 administrative order change charge.

We do our absolute best to ship your within 2 days depending on time of order. If ordering blanks it takes a few weeks to manufacture them and we work each shipment in the order we receive them.

You will receive a tracking number email when your order ships. Check your spam folder if you did not see it.

You can also log into your online account and view the status of your order.

We didn't receive any orders so you were not charged, out payment gateway declined the card for address or zip code discrepancy. Your bank marked your attempts as "pending" and hold it for 2-3 days.

More info on why you see it as a charge here:

The merchant is telling you the transaction was declined, and your bank is telling you it has been approved. Yes, your bank approved the transaction but the merchant's payment gateway declined the transaction so the entire transaction was declined even though your bank approved it. Merchant's payment gateway may have security settings which may have triggered a decline such as address and zip code verification. It is the way how the banks operate, so it's not your fault nor merchant's fault. The merchant cannot remove the charge since it was never approved, so please do NOT ask merchant to remove this charge. The charge will be on "pending" state, and the money will never be taken out of your credit card account but the reserve will be put aside so it will reduce your credit limit until the transaction clears on it's own within 2-5 business days. The bank will say "ask the merchant to call in to cancel this transaction", but a merchant CANNOT call in on your behalf as the credit card companies will not share account information with non-account holders such as a merchant.

To understand why this is happening, you'll have to understand how credit card transactions are processed. For full explanation, please read the Credit Card Processing Diagram with explanation below.

1. When a buyer commits an order, the credit card transaction goes to the payment gateway provider such as Authorize.Net and forwards the transaction to Merchant Bank's Processor.

2. The information is then sent to your bank ("issuing bank"), and your bank will either approve or decline the transaction based on customer's available funds. If transaction is declined by your bank, the transaction stops and there is NO problem. The customer's bank account will show transaction declined and so does the merchant's processor so there is no reason to argue with the merchant or bank.

3. If the transaction is approved by your bank, now the transaction is once again go through a security check by the payment gateway company with billing information sent by the issuing bank. If customer entered address, zip code and card code do not match with the credit card billing information provided by the issuing bank, the payment gateway may decline the transaction based upon merchant's fraud security settings. This is the reason why your bank says it's approved, and your merchant says declined -- and, they are both right!! Your bank approved the transaction, but the payment processor declined the transaction.

To conclude, the net result of transaction status is a failure as the payment processor declined the transaction even though your bank approved it. This transaction will NOT show up on your credit card statement as it is declined by the payment processor. To your bank, they'll see this transaction as approved and will temporarily hold ("reserve") this money until the payment processor claims the money (which will never happen as it is a declined transaction), or a specific time elapses with no action from the payment processor which then releases the reserve. The time it will take to release the fund varies from banks to banks, and it could take anywhere from 2-7 business days.

The reason for multiple "approved" transactions on your bank account may be due to multiple attempts on your part to submit the order when the payment processor declined the previous transaction.

Why would payment gateway company scan a security check and decline the transaction when the issuing bank already approved the transaction? Credit card fraud is one of the fastest growing crimes as more and more people are buying products and services online. When fraud occurs, the banks get their money back from the merchant and the customers get their money back from the banks (with a bit of hassle). It is the merchant who will lose money on fraudulent transactions. To protect merchants and buyers, payment gateway providers implemented additional security check to prevent "possible" fraud.

Note: You may reproduce and distribute contents of this article provided that you give a full credit to the author ("Scott Seong"), and provide a backlink to this page from your webpage. The content shown below is borrowed from Authorize.Net, and we do not have an authority to grant permission to redistribute it's content.

Credit Card Transaction Workflow Diagram

Source: Authorize.Net

1. The merchant submits a credit card transaction to the Authorize.Net Payment Gateway on behalf of a customer via secure Web site connection, retail store, MOTO center or wireless device.

2. Authorize.Net receives the secure transaction information and passes it via a secure connection to the Merchant Bank's Processor.

3. The Merchant Bank's Processor submits the transaction to the Credit Card Network (a system of financial entities that communicate to manage the processing, clearing, and settlement of credit card transactions).

4. The Credit Card Network routes the transaction to the Customer's Credit Card Issuing Bank.

5. The Customer's Credit Card Issuing Bank approves or declines the transaction based on the customer's available funds and passes the transaction results back to the Credit Card Network.

6. The Credit Card Network relays the transaction results to the Merchant Bank's Processor.

7. The Merchant Bank's Processor relays the transaction results to Authorize.Net.

8. Authorize.Net stores the transaction results and sends them to the customer and/or the merchant. This step completes the authorization process – all in about three seconds or less!

9. The Customer's Credit Card Issuing Bank sends the appropriate funds for the transaction to the Credit Card Network, which passes the funds to the Merchant's Bank. The bank then deposits the funds into the merchant's bank account. This step is known as the settlement process and typically the transaction funds are deposited into your primary bank account within two to four business days.

Why is my credit card zip or postal code not matching?

When your payment fails due to an incorrect zip or postal code, this means your bank told us your security code matched, but not your zip or postal code. To protect both you and us, we decline non-matching transactions to fight fraud.

How we process payments

- We send a charge request to your bank for approval

Your bank may both approve the transaction and tell us something didn't match -- in this case, they specified that only the security code matched, but not the zip/postal code

- To protect you against fraud, if either the zip/postal code or security code don't match, we reject the transaction

- For some banks, this can leave a temporary pending (but unsettled) charge on your account. It will fall off your card shortly, usually within 24-48 hours.

To get to the bottom of this, you need to find out why your bank is telling us that the information we are submitting with your payment does not match what they have on file for you. When you call your bank, they may initially tell you "we approved that charge". You have to be more specific with call center staff and ask "Why did the AVS not match? What zip code did you receive and what do you have on file for my account?"

| Yes! We ship to

all corners of the world with USPS. Our webstore automatically calculates

international shipping costs based on the weight of your

package. At this time we cannot resins, resin additives,

or surfboard blanks and kits to international

addresses. |

Please read our blank shipping information page. You can order blanks online and the shipping options will appear in the checkout for domestic US addresses. |

| Yes, we can ship blanks and resin within North America no problem. The costs of shipping blanks and resins internationally (overseas) is extremely high. If you want to purchase larger volumes of product it becomes affordable on a container but small shipments are usually at least 5 times the cost of the product. Please contact us if you have large volume requests. We have customers in the Caribbean, Puerto Rico, Peru, Chile, Costa Rica, and the UK who we ship larger quantities of blanks and resin to. |

| Click HERE for our blank shipping info and costs. We can fit up to 4 blanks per box if you would like to lower your shipping cost per blank, and can ship 3 full boxes of blanks (12 blanks) for the same cost as shipping a single blank. |

| That's

correct Greenlight's unglued EPS blanks 6'6" and under ship UPS Ground to your door. Shipping costs are calculated in the webstore's cart and based on your location. Please visit our SHIPPING INFO page for detailed costs on blank shipping |

All orders are shipped as quickly as possible. Some are same day, most are next day unless it is a blank order which we manufacture per order. Blanks ship out in about 3-4 days depending on the quantity you've ordered. We use USPS and UPS depending on best rate for your shipment. East coast addresses usually receive their shipments in 3-5 business days. Middle states 4-6 business days. West Coast 5-7 business days. Canadian customers expect 5-10 days as the shipment must go through customs office. All other international customers expect 21 days to receive your order. You will be emailed a tracking number for your order. Please check your spam folder if you do not receive it. Please do not email us asking where you order is. The tracking number has the answer. If you do not receive your package in the estimated times stated above, please email us the tracking number and we will take care of it. |

Please visit our SHIPPING INFO page for detailed costs on blank shipping

You can order blanks online and the shipping options will appear in the checkout for domestic US addresses. |

Absolutely. Please select "pickup at shop" in the checkout For stock PU Blanks (US BLANKS and ARCTIC) they are ready to pick up immediately. Engineered EPS Blanks are made to order and we'll email you when the blanks are ready. It's usually 4-5 days to get to your blank order. |

Yes. We can ship all products including Blanks and Resins to Canada. Shipping rates are calculated in the store's checkout. MORE INFO ON OUR SHIPPING PAGE We also have options ship to a freight warehouses on the US border for you to pick up. It is much less expensive to ship there as opposed to over the border. If shipping blanks please email us for a shipping quote as we work with several cross-border freight companies to find the best price for you.You are responsible for Duty and brokerage fees for the shipment. We recommend contacting one of the freight brokers below to clear your shipment through customs: http://www.shipnorthamerica.com/htmfiles/brokerage.htm |

1. We can ship to one of the following freight centers on the US border for you to pick up and drive back over the border. There is a small warehouse fee for these freight centers. You clear through customs at the border. This saves a lot of shipping cost for you as the freight companies almost double the fees to get your products across the border and deliver to you.

NEW SEPT 2017! Have your blanks shipped to a warehouse with the KinekPoint Service! Dozens of warehouses on the US border we can ship to.

Freeport Forwarding - Champlain, NY (Approx 1 hour from downtown Montreal)

Bee Line Logistics - Champlain, NY

Pinnacle Parcels - Richford, VT

Shiretown Package and Receiving - Houlton, ME

CBI - Niagra, NY

Absolutely, you can pick a kit up at our shop in Manasquan. Please select "pickup at shop" and allow us to email you when the blanks are ready as we manufacture them onsite per order. Might take up to 2 weeks depending on how busy we are.

| We cannot hold blanks without payment. Please order the blank online and select 'pickup at shop' for the shipping option to make sure you get it. |

We are an independent distributor for US Blanks but offer a

different and faster service than Florida actually. |

All orders are online.

If you are purchasing an EPS blank we fabricate them per order and please allow up to 2 weeks to pick up. We'll email you when it's ready.

US Blanks are stock items you can order online and select "pick up at shop". We will notify you when they are out in the pick up area.

Shipping costs, both domestic and international are automatically calculated by the webstore based on total weight of the order and your location. Shipping costs for blanks is a little more involved. Click here for more info on blank shipping costs. Keep in mind we can ship your fiberglass, resins, fins, tools, etc with the blanks in the same box for no additional cost

Please visit our SHIPPING INFO page for detailed costs on blank shipping

Returns & ExchangesOur policy lasts 10 days. If 10 days have gone by since you received your purchase, unfortunately we can’t offer you a refund or exchange.To be eligible for a return, your item must be unused and in the same condition that you received it. It must also be in the original packaging. There is a 15% restocking charge for returned items.Non-returnable items:Gift cardsDownloaded / Digital productsTo complete your return, we require a receipt or proof of purchase and an RMA # (Return Merchandise Number) to be written on the outside of the return shipping box. Please contact us before sending the item back for your RMA#.Please do not send your purchase back to the manufacturer.There are certain situations where only partial refunds are granted (if applicable):1. Any item not in its original condition, is damaged or missing parts for reasons not due to our error2. Any item that is returned more than 10 days after deliveryRefunds (if applicable)Once your return is received and inspected, we will send you an email to notify you that we have received your returned item. We will also notify you of the approval or rejection of your refund.If you are approved, then your refund will be processed, and a credit will automatically be applied to your credit card or original method of payment, within a certain amount of days.Late or missing refunds (if applicable)If you haven’t received a refund yet, first check your bank account again.Then contact your credit card company, it may take some time before your refund is officially posted.Next contact your bank. There is often some processing time before a refund is posted.If you’ve done all of this and you still have not received your refund yet, please contact us at info@greenlightsurfsupply.com.sale items (if applicable)Only regular priced items may be refunded, unfortunately sale items cannot be refunded.Exchanges (if applicable)We only replace items if they are defective or damaged*. If you need to exchange it for the same item, send us an email at info@greenlightsurfsupply.com and send your item to:Greenlight Surf Supply187 Parker AveManasquan New Jersey US 08736

*Damage to items from improper use, storage, abuse or user error is not eligible for exchange.GiftsIf the item was marked as a gift when purchased and shipped directly to you, you’ll receive a gift credit for the value of your return. Once the returned item is received, a gift certificate will be mailed to you.If the item wasn’t marked as a gift when purchased, or the gift giver had the order shipped to themselves to give to you later, we will send a refund to the gift giver and he will find out about your return.ShippingTo return your product, you should mail your product to:Greenlight Surf Supply187 Parker AveManasquan New Jersey US 08736You will be responsible for paying for your own shipping costs for returning your item. Shipping costs are non-refundable.If you are shipping an item over $75, you should consider using a trackable shipping service or purchasing shipping insurance. We don’t guarantee that we will receive your returned item.

We can ship EPS foam blanks in half for less than the blank glued up. We also ship Polyurethane foam blanks glued up but it costs more.

If you want to order an EPS foam blank the Canada shipping cost will be available in the webstore's checkout.

Stringer is included with the blank, the glue is separate and can be purchased HERE.

Unfortunately the shipping companies do not just weigh the order. They've devised what's called Dimensional Weight = (Length X Width X Height)/194. The large dimensions of the blanks (even shortboards) make the weight look like 100+lbs and therefore expensive to ship. They have to be moved on a tractor trailer and are called "freight".

We work with multiple freight companies to negotiate the lowest possible shipping costs possible for you on every surfboard blank order.

But Greenlight has developed a way to ship Engineered EPS Surfboard Blanks under 6'6" to your door with UPS Ground for about 60% less cost than a freight truck. We ship the blank to you unglued to make the package smaller. Our EPS blanks have flat edges so glue up is really easy with clamps or even just stack the pieces vertically on the floor and apply pressure while the glue dries.

You will be emailed a tracking number for your order. Please check your spam folder if you do not receive it. Please do not email us asking where you order is. The tracking number has the answer. All orders are shipped as quickly as possible. Some are same day, most are next day unless it is a blank order which we manufacture per order. Blanks ship out in about 3-4 days depending on the quantity you've ordered. We use USPS and UPS depending on best rate for your shipment. East coast addresses usually receive their shipments in 3-5 business days. Middle states 4-6 business days. West Coast 5-7 business days. Canadian customers expect 5-10 days as the shipment must go through customs office. All other international customers expect 21 days to receive your order. If you do not receive your package in the estimated times stated above, please email us the tracking number and we will take care of it. |

Sure, I recommend getting our shaping tool kit and our beginner glassing kit with epoxy (we can usually get epoxy through customs).

Yes, but we do not ship blanks or resin to Europe at this time, too cost prohibitive. We do ship small items like tools and materials to Europe daily though.

Yes, we ship to most international countries. We

can ship anything but blanks and resin to international

addresses. International

shipping rates are calculated in the store's checkout. Just make a shopping

cart and enter your address. Local customs charges may

apply. All packages are sent via United States Postal

Service (USPS). Orders may be subject to import duties and taxes, which are levied

once your package reaches

your country. Greenlightsurfsupply.com does not collect import duties and

taxes and cannot predict

these particular charges. These duties and taxes are not included with the

freight calculation and are

the responsibility of the customer. For information regarding your

country's customs policies, please contact

your local customs office. |

| We can ship anything but blanks and resin to Mexico. International shipping rates are calculated in the store's checkout. |

Yes, we ship to Britain. Pounds are

automatically converted to USD when your credit card is processed in the

webstore. No problem. Shipping costs are calculated in the store's

checkout based on weight of products. Please note we cannot ship resins or blanks

internationally. |

Yes we ship to FPO/APO addresses. Our webstore will not recognize an FPO address so please let us know what you'd like to purchase and we'll send you a secure payment link. No problem.

Very expensive to ship blanks overseas. You have to buy a lot of blank to make it worth the shipping costs

Yes, we certainly do ship to AU all the time. International shipping costs are calculated in the webstore's checkout based on total weight of the order.

Shipping the blanks across the country to BC is about $400. The total weight of the order will determine the exact cost. When shipping blanks its always better to get more because they don't weigh much and the shipping costs do not increase much with multiple blanks.

Here is a link to the Canada Duty Calculator

Some shipments such as blanks will require a customs broker to clear your produts across the border.

Here are a few brokers to contact for info:

http://www.shipnorthamerica.com/htmfiles/brokerage.htm

http://www.aacb.com/

http://www.pcb.ca/

Small shipments with USPS do not require a broker.

SURFBOARD BUILDING QUESTIONS

Our beginner surfboard shaping kits include everything you need to get started shaping boards at home by hand. All the materials, tools, instructions, safety equipment, and support. All you need extra is wood and screws to build your shaping racks. We even give you padding for the shaping racks you build and a free outline template of your choice from our Template Library.

The only thing not included is the fin boxes and fin install supplies since that is a personal preference and usually depends on what type of fins you currently own.

The beginner kits come with an Engineered EPS blank and epoxy resin so you can build a stronger board that will last (most people keep their first shape as a memory of the fun) and it's much less toxic and smelly than glassing with polyester resin so you can do it in your garage or basement without stinking the whole house up!

We ship the beginner kits to your door with UPS to reduce the shipping costs.. you will glue the blank halves and stringer together in a simple process. Here's a video of how to glue your blank to save about $100 in shipping costs!

Yes. We have a longboard shaping kit.

Contact us for shipping quote.

For a first timer, the least expensive fin system to install is FCS X-2 Plugs, [2 plugs per fin... for a tri fin you'll order 4 RAIL plugs and 2 CENTER Plugs, if you're making a quad fin order 8 RAIL plugs as the RAIL Plugs have a fin cant angle molded in] FCS X-2 Plugs only require a normal power drill, X-2 Holesaw bit. and quick set jigs.

Here's how to install the X-2 plugs and a diagram of standard fin placements:

The things that we would suggest to make this an easy install are the FCS dummy install jigs and a g square or versasquare for laying out fin placements. The quick set jigs are an easy one time use product and the g square or versasquare is a tool you will use forever in your board building...

NOTE: For EPS boards use Resin Research Quick Kick Epoxy to reduce exotherm and prevent melting the foam. See Step 4.

1. FCS X-2 and FACTORY plugs are installed after the hotcoat. After installation and the resin has cured, you sand them down flush with the board while sanding the bottom.

2. Once you have the quickset jigs laid out on the board (lined up with your shapers dots) you will use a FCS Hole Saw bit to make your holes for the plugs. Drill the hole 5'8" deep and pull the foam out with needle nose plyers or dig out with a flathead screw driver.

3. We suggest using either FCS dummy jigs or a set of fins to set the plugs with the correct spacing as well as adjust the fin cant angle. Lightly screw the plugs onto the dummy jig tabs. If using fin keep the plugs loose on the fin tabs so you can push them down to where the "nubs" on the plugs touch the hotcoat.

4. Polyester boards: Mix 1 oz of resin per plug. (6 oz total for a tri-fin, 8 oz total for a quad).

EPS boards: Use Resin Research Quick Kick resin. In temperatures hotter than 80 degrees F, mix 1/2 oz per plug. You will fill the plug hole twice to reduce exotherm and prevent melting the foam.

5. Polyester Board: Pour about 1/3 oz of mixed resin into the holes.

EPS Board: Pour about 1/2 oz mixed resin into the holes.

6. Place the plugs in the holes with the dummy jig or fins to ensure proper alignment. Set the fin cant to the desired angle and hold in place with tape. Here is an illustration of taping the fins in place (these are glass ons but same taping methods apply to FCS fin plugs)

7. Polyester Boards: Using a small cup (dixie cups work great) carefully pour resin around the perimeter of the plug so it runs into the drilled hole. Be careful not to over fill! Fill just under the lip of the plug and jig.

EPS Boards: In temps above 80 degrees F, let the first pour cure for about 2 hours then mix another 1/2 oz Quik Kick resin per plug an top off.

Once the resin cures remove the jigs and sand the plugs down until they are flush with the board.

______________________________

Three other fin box options that are installed before fiberglassing your board are:

We also have FCS Fusion fin plugs which require a Fusion Install kit and trim router.

Another option is the new FCS II fin system which require a FCS II Install kit and trim router.

or

Futures Fin system which requires a Futures intstall kit with router

Our Surfboard Shaping Starter Kit includes all the materials, tools, and instruction needed to build a surfboard. Only thing needed to purchase is a leash and fins from a surf shop when complete.

Also your daughter will need to build shaping racks from wood and fiberglassing racks from wood, buckets and a bag of cement or sand. The total cost for those materials from Home Depot is about $30

The logo rice paper can be printed on with an inkjet printer, or drawn on with posca pens, acrylic paint, or india inks. Do not use sharpie markers as they will bleed when wet out with resin.

It is best to put the logo paper directly on the foam on the bottom of the board, and in between the two layers of fiberglass on the deck to protect it from sanding. You can also put it on top of a cured lamination and put a small piece of fiberglass over it. We use 1.5 oz fiberglass for this. It is common for board builders to laminate the board with a dark color pigment then put the logos on top of it with the 1.5 oz fiberglass cloth protecting the logos.

Consistent High Quality

Greenlight has teamed up with a major plastics manufacturer to design the optimal bead and compression process for EPS surfboards to improve surfboard strength, flex, practical weight, and shapability. We've even engineered the rocker and foils in our blank selection to yield any board you can imagine with the least amount of effort by hand or machine.

Our engineered EPS Blanks can also be customized to any thickness for a super close tolerance blank that requires very little shaping without the expense of paying for a machine shape.

Greenlight's Engineered EPS Blanks Advantages:

- Reduced Bead Tear out

- when Shaping by Hand

- or Machine

- Low Resin Absorption

- Calculated Rocker and Foil Designs

- Completely Customizable

- Quick Turn Around Time

Surfboard are made from (and we sell) two types of foam blanks.

1. EPS Blanks - EPS stands for Expanded Polystyrene. EPS foam is lighter and stronger than Polyurethane foam blanks. It consists of small beads of polystyrene expanded with steam and fused together under high pressures. Greenlight's EPS blanks are engineered with a special bead formula for the optimal strength, flex, and shape-ability of the blank. There is a growing demand for EPS surfboards in the world due to its superior strength to weight ratio.

The EPS blanks are rectangular in shape supplied with a rocker and foil. You can create any outline shape you want with EPS blanks.

Greenlight is a huge proponent of EPS surfboards and has been developing, manufacturing and selling EPS blanks for over 10 years.

NOTE: EPS foam must be glassed with EPOXY resin! Polyester resin will melt the foam!

2. PU Blanks - PU stands for Polyurethane. It has been the standard surfboard core for over 50 years. PU blanks can be glassed with either polyester resin or epoxy resin (epoxy becoming more popular due to its superior strength). PU blanks are molded in the general shape a surfboard to reduce the amount of excess foam. Your surfboard shape outline still must be drawn on the blank and cut out.

EPS stands for Expanded Polystyrene. EPS foam is

lighter and stronger than Polyurethane foam blanks.

It is also recyclable.

There is a growing demand for EPS surfboards in the world due to

its superior strength to weight

ratio. Greenlight is a huge proponent of EPS surfboards and has

been developing, making and selling

EPS blanks for over 10

years. We have engineered our own EPS foam that is the only EPS foam specifically designed for surfboards on the market. NOTE: EPS foam must be glassed with EPOXY

resin! Polyester resin

will melt the foam! |

We manufacture all EPS blanks here at the shop and can cut up to 12' long. Please email info@greenlightsurfsupply.com with your blank dimensions and stringer option and we'll give you a quote.

We can also take a AKU Shaper, Shape3D file or .dxf file you design and cut directly from that.

PU stands for Polyurethane. It has been the

standard surfboard core for over 50 years. PU blanks can

be glassed with either

polyester resin or epoxy resin (epoxy becoming more popular due to its

superior strength). |

US Blanks have a general surfboard rocker and outline. You will need to cut an outline with all blanks that we sell. When selecting a US Blank you should try to find a blank that fits the dimensions of the board you are trying to shape. US blanks are a close tolerance blank which mean that the outer part of the blank is the strongest foam and as you get closer to the center the foam will get softer, which makes blank selection critical to the strength of your surfboard.EPS blanks are uniform density throughout so you can get one a bit thicker than your finished board dimensions and shape away. EPS blanks are hotwire cut from a block of foam and have a rectangular outline which allows you the freedom of any outline you choose to cut. |

Sure, we'll split your EPS blank no problem. Just put a note in the order to split the blank.

You can glue it up with a stringer or as a stringerless with Gorilla glueOur Engineered Expanded Polystyrene (EPS) is available in our Engineered 2# cubic foot density. Other densities (1#, 1.5#) available upon request.

US Blanks - we stock BLUE density (medium). Lighter and Heavier desities (red, green, brown) available as a custom blank upon request.

| We use those letters to differentiate shapes of the same length. If you would like to let us know what you are interested in shaping we can help steer you in the right direction. |

| Yes, you will need to draw a template on the board and cut it out to get your desired shape. We offer a selection of printable templates on our site if you are looking to get a pre made template. |

| Our EPS blanks all have square noses and tails so you can make any shape you want. |

Your son should get an "Up to 6'6"

Fish, Egg, or Shortboard' or "Up to 6'4" Shortboard" beginner

shaping kit. It depends on the type of board your son wants to

shape... our 6'6" long kit is designed with extra foam in the surfboard

blank to get the feel of shaping without ruining your

efforts. We can ship the kit to

your door or

you can pick up at our shop if you'd like. |

You could use another longboard blank and 'flip" it so the nose rocker would be used for the tail (as long as your outline template fits in the nose area [which would be the tail of the blank when you flip it]) Some guys flip the US Blanks 98Y for nose rider designs.

Or we can custom order you a blank to whatever rocker you want. No problem.

For the 9'2" go with the US Blanks 93Y or

94B depending on the rocker you want to get. I'm not familiar with the Gold

Standard rocker but my guess

would be the 93Y. US Blanks 84SP for the funshape and either a US

Blanks 510RP or 6'2A for the mini simmons depending on your preference of

nose rocker (510 more, 62A less..) 2 layers 6 oz deck / 1 layer 6 oz bottom for the

longboard... or if you wanted to keep it lighter for your girl to carry

you can do a 6/4

deck. |

| US Blanks have a general surfboard rocker and outline. You will need to cut an outline with all blanks that we sell. When selecting a US Blank you should try to find a blank that fits the dimensions of the board you are trying to shape. US blanks are a close tolerance blank which mean that the outer part of the blank is the strongest foam and as you get closer to the center the foam will get softer, which makes blank selection critical to the strength of your surfboard. |

All our blanks available are listed on our website. Here's a link to the blank page. We manufacture EPS blanks per order so please give us a few days before picking up.We carry US Blanks, Common Surf Foam, and cut EPS in 2.0#, 1.5#, and 1# densities. Quantity discount pricing is shown on each blank page. You can order online and we'll have them ready for you to pickup. Feel free to contact us anytime if you have a question |

US Blanks and Common Surf Foam are PU blanks (polyurethane foam)

It has been the standard surfboard core for over 50 years. PU blanks can be glassed with either polyester resin or epoxy resin (epoxy becoming more popular due to its superior strength).

EPS stands for Expanded Polystyrene. EPS foam is lighter and stronger than Polyurethane foam blanks. It consists of small beads of polystyrene expanded with steam and fused together under high pressures. Greenlight's EPS blanks are engineered with a special SWELLBEAD formula for the optimal strength, flex, and shape-ability of the blank. There is a growing demand for EPS surfboards in the world due to its superior strength to weight ratio.

Greenlight is a huge proponent of EPS surfboards and has been developing, manufacturing and selling EPS blanks for over 20 years.

NOTE: EPS foam must be glassed with EPOXY resin! Polyester resin will melt the foam!

Here's a link to the blank glue up instructional video: https://youtu.be/

The video can also be found on each EPS blank product page

Yes we have foam cutting files for various skimboard sizes. We can provide you an EPS foam blank any length in 2# density. Please contact us for a quote.

Yes, we have wakesurf board blanks and complete wakesurf board building kits available.

Please click here for our WakeSurf Board Building Section

Don’t believe all the hype, EPS is great to shape. A good deal of our customers prefer to shape their boards with it. We all use just a regular planer and do not switch out the blades. We would recommend our Pro Tool series as they were designed to take down foam fast and efficiently, especially EPS beads.

We use AKU Shaper .brd files, Shape3D .3dx files, or Autocad .dxf files. But you can send a pdf and we can trace it. Or just rocker numbers and we'll create the file for you. No problem.

Cost depends on length, foam density, and stringer material. Send a file over and we can quote it.

Venting an EPS board is like an "insurance policy" to prevent delamination. EPS boards contain very small air pockets between the foam beads which expand and contract with changing temperatures. If a board is dinged while surfing and water gets in, additional heat (leaving your board on the beach or in a hot car) will cause the water to change phase in to steam and exert pressure on the fiberglass skin - pushing the glass away from the foam (delamination).

It's up you to if you want to install a vented leash plug in your EPS board but we developed the VXVs because so many personal boards were having issues when not vented. Since installing VXVs in boards there has not been a single delam due to water expansion in a board in years.

*It is highly recommended to install vented leash plugs in stand up paddle boards due to the large volume of foam that will expand and contract more in varying temperatures. All the major SUP manufacturers vent their boards with either a vented leash plug or a deck vent.

It is popular to "Flip" a stock blank to increase the tail rocker and lessen the nose rocker. This is also called Reverse Rocker.

A lot of guys just template the board with the at the tail of the blank if the outline fits.

We can easily build you a reverse rocker blank in any size if your outline templates don't fit on a stock blank that is flipped.

EPS blanks do not need to be sealed but sealing helps to use less resin and also provides a bright white uniform surface if you are doing color or artwork on the board.

You can simply squeegee lightweight spackle on the board (mixed with bottled water to a mayonaise consistency) in a thin later to fill the small holes between the beads, or mix up a paste of epoxy and Q-cell and squeegee that on (makes a stronger board).

There is also the option of finish sanding the board to 320 grit sanding screen to close up the cavities between the foam beads.

The glue up simply holds the blank together so you can shape it. An uneven glue up will just be a little more shaping to level everything out. Glassing the board provides all the strength and the glue is not really a factor in the board.

If you have space between the foam and stringer you can squeeze more glue in. It will expand to fill the gap and is shapeable.

Our Engineered EPS foam does not require sealing. We recommend screening your final shape with 150 grit sanding screen to tighen up the bead structure for less resin absorption into the foam.

Sealing with lightweight spackle is highly recommended when glassing resin tint laminations or if you are painting the blank to give the blank a flatter surface for uniform color (no darker pools of resin)

The answer to your question is covered in detail on the first page of our Surfboard Building Guide. Please read through the guide to understand the entire process and you'll be confident in starting to shape your own boards.

Our new foam is a consistent density throughout the blank and designed with a special mix of EPS beads that have high energy bond strength that reduces tear out and resin absorption. We could call it super duper fused but it's just marketing words. I've shaped "superfused" blanks that chunks of the rail blew off with one pass of the surform...

The blank rocker and foils are also special since we took a lot of time studying current modern rockers and designed the series of blanks to easily fit just about any board possible.

You can use epoxy resin but we recommend using Expanding Stringer Glue as it cures fast and is easy to sand.

Tear out is nothing to "worry" about. It is part of the process of shaping EPS. Our foam is the tightest bead bond in the industry but you will still get some beads that pull out. The idea of shaping EPS to to rip into it with the most aggressive tools to remove the foam them go over it with finer grits of sandpaper or sanding screen to close the small bead voids up.

If you are painting or doing a resin tint it is advised to apply a thin coat of lightweight spackle on the board to make it a clean, bright white surface to have even color.

A clear glass job or opaque pigmented resin lamination does not require spackling.

No big deal. If you have more Stringer Glue left just squeeze it in the void and it will expand. It's foam too and easily shapeable. If it looks weird you can put a logo over the area, paint the board, or do a pigmented lamination to cover it.

You can design a file from free design programs like AKU Shaper or Shape3D software and upload it when you order a custom cut close tolerance EPS surfboard blank.

You can just email the specs of your blanks, length, thickness, nose and tail rockers and we'll draw it for you.

Or you can send a file from free design programs like AKU Shaper or Shape3D software and we can work with that.

When the glue is fully cured you'll be able to peel it off your skin. Maybe rub some sandpaper or file on it to break it up. We're peeling glue off body parts all the time here

Your stringer choice really depends on performance and style. 1/8" basswood stringers have been standard for decades and work really well. Our new HD foam stringers give the board more "pop" out of turns and are just as strong as the 1/8" basswood. The HD foam stringers also give you a choice of color and can be shaped with the same tools as used on the foam. No wood tools needed.

In the end, the snap resistance of a board really depends on the amount of fiberglass you put on the board. An all 4 oz glass board is much more susceptibe to breaking than a board with a mix of 6 oz and 4 oz glass or an all 6 oz glassed board (longboards or old school fish).

The gap is no issue for strength of the board, the fiberglass shell is 90% of the strength after glassed. To make it look good you can squirt more glue into the gap and let it expand. If you have clamps then use them to pull the foam to the stringer and it will be 100% glued correctly.

If you're doing a clear, white board or pigmented lamination no need to seal. You can leave the finish at around 80 grit and glass, or tighten up the beads with higer grits up to 220, although there is no real benefit going past 80 grit.

If painting or tinting the resin you can seal the blank with EPS Sealing Paste to close the voids in the foam and provide a clean, bright white canvas do you your artwork on.

The template letters next to the length are just to identify different templates of the same length.

The best noserider template we offer in my opinion is the 9'6W as it is designed with a wider nose and square tail for nose riding. The other templates are more high performance or cruiser designs.

Sorry we don't make custom templates. Please refer to our Surfboard Shaping Guide for different methods of making your own templates.

The stock templates we have are all HERE on the site. They are starting points for your shape. You can make a single fin from any of them or modify the template to what you feel looks right.

| Read our Surfboard Building Guide A-Z. Making templates if covered in the writeup. |

If your board is over 8'

long and you need to make a two-sided 'spin' or 'flip' template, you

simply draw the nose half of the board on one side of the template, and the

tail half of the board on the other side. Just make sure that you mark stringer points on both ends and top/bottom of the template to mark the

point where you will place the template down on the stringer when you trace

your outline on the surfboard blank. |

There are no standard dimensions for a surfboard

rocker (the stringer) since it all depends on the waves you surf and how you

want the board to

perform. Stock

surfboard blanks have proven rockers that are a great starting point and

maybe a little adjustment is needed while shaping to get the desired rocker

you want to

surf. Typically, if

you are making your own stringer, you simply trace the blank foam outline on

a piece of wood and cut out to match. Then glue it all

together. If

you want some dimensions to start you can copy the rocker on

our 6'3

Fish blank |

The 12'6" SUP outline template has parallel rails through the middle of the board so you can take out sections of the middle to reduce the length without changing the overall shape. No need to specify the length you want when ordering.

To make the board wider you simply move the template away from the stringer and draw curves on the blank to extend the outline to the stringer. You can do it free hand, make your own paper template for the extensions, or bend a flexible piece of wood, plastic, or metal to get your extension curve.

Sorry we do not supply rocker templates. There are no standard dimensions for a surfboard rocker (along the stringer) since it all depends on the waves you surf and how you want the board to perform.

Stock surfboard blanks have proven rockers that are a great starting point and maybe a little adjustment is needed while shaping to get the desired rocker you want to surf.

Extensive info on ROCKER can be found in our Surfboard Design Guide

There is no physical railband template but we provide the rail band dimensions to lay out on your board. The dimensions depend on thickness of the board and out chart is made for a 2 1/2" thick board. A little math is needed to calculate railband dims for other thicknesses.

The railband numbers can be found in our Surfboard Building Guide, here they are as well.

Railband Reference drawing for a fish

When using templates it's always a good idea to measure out the width you want the board to be and pencil in a dot at the widest point on each side of the stringer. Then line up the template to that dot and parallel to the stringer. Then trace the line and connect the nose and tail lines if needed.

Templates are all about the curves that work well in the water and not so much about numbers.

We designed the templates to be any width you want by moving it closer to the stringer for a narrower board or further for a wider board. We believe you should have control over the design and dimension of your board and not be locked into a board that is designed for someone else.

Our templates are mostly all about the curve and the flow of water around the plan shape. Width dimensions only determine the rail-to-rail stability of the board.| Please review the

Surfboard Shaping section of our Surfboard

Building Guide for general info in shaping a surfboard, Stand Up

Paddleboard, Kiteboard, Wakeskate,

etc. If you have specific questions on surfboard shaping, please enter search terms in this extensive FAQ & knowledge database to find your answer. If the answer to your question is not in our HELP CENTER, please email info@greenlightsurfsupply.com for assistance. |

| Your nose and tail rail marks can vary by the nose and tail

depending on the type of board you are shaping. In a high performance shape

you will have a rail mark at the nose that is 1/2" and the center and

tail marks at 1" to account for the foil of the board as shown

here Each board can be a little different so don't be afraid to adjust the numbers slightly to account for the rail thickness you desire. Reference: Simple Rail Bands Chart - (midpage) Boxy Rail Bands Knifey Rail Bands |

The "fred tool" part of the rail runner is for the bottom tuck only. The bottom tuck is normally anywhere from a 3/8" - 3/4" radius (depending on your preference) and the rail bands are cut in the the rail runner.

The deck rail bands are much bigger and not a "radius" but an arc or curve. The rail bands are created with a power planer or G-rasp tool and the sharp corners of the rail bands are cut down by rail screen (you should be using a more aggressive screen like the sand shark screen to shape the rails down... they'll come out round and less angular or boxy)

Think of the rail bands as facets of a diamond. Flat surfaces intersecting at points. There is a curve hiding in there that is exposed when the corners are screened off.

More info and dimensions for rail band shaping in our Surfboard Building Guide

| Any

planer will work to shape a board. We offer an entry level electric power planer that works great for shaping all types of foam and is simple to use. The Hitachi modified planer is a surfboard specific planer with on the fly depth adjustment, a bit more power, and better dust control. The modified Hitachi makes shaping railbands much easier and allows you to shape your surfboard's foil and rocker fluidly as you can adjust the depth of the cut while walking the board. It is a great tool for the experienced shaper or anyone that plans on shaping a bunch of boards. You can also use a stock planer like a Bosch, Dewalt, Makita, etc. The planing techniques are different since there is no adjustability but the goal is to remove foam quickly with a planer, which stock planers off the shelf will do. There is just more hand shaping with a G-rasp and Rasputin involved when using a stock power planer. Another note, if you choose a stock planer make sure it has 2 blades for a smoother cut on foam. A single blade power planer will tear the foam like crazy and make more work for you! |

| We can supply you with all of the materials that you need. We would suggest EPS foam and epoxy resin with some 4 oz fiberglass. If you would like to use a strap system we would suggest a 4 leash plug setup. If this fits your needs we can get a handplane kit setup for you. Just shoot us and email with your handplane blank request info@greenlightsurfsupply.com |

| To fill in any marks we spackle the entire board with light weight white spackle. Then you can take screen and smooth out all the spackle once it has dried. This is purely an aesthetic step to give the board a perfect look to the finish. |

| We suggest laminating a strip of

the Uni

directional carbon fiber along the centerline of the bottom of the board or you can

wrap the rails with the Uni directional carbon fiber for more torsional

strength. You can also laminate the bottom of the board with VectorNET

carbon fiber reinforcement for additional

strength. It is recommended to do at minimum lamination of 1 layer 6 oz

and 1 layer 4 oz on the deck to reduce pressure denting from your

feet. |

Absolutely, the 6'6" blank is designed for

first time shapers and you can make any size board from it up to 6'6".

Our paper templates work well

on all blanks. |

| Our Railband dimensions are in the Shaping section of our Surfboard Shaping Guide. |

Due to the nose rocker curve in the deck of a

surfboard planer blades cannot easily get to the foam in that area. A trick

is to turn the planer on an angle so the barrel is more parallel to the

stringer in the nose curve area. It's not easy and most beginners

just use a G-rasp

or tigershark

paper on a hard block to shape that

area. |

| A spokeshave is the tool you want to take down the stringer. |

Most blanks do not need a lot of added rocker

since the blanks are designed with proven curves. Blank selection is

very important. If

adding more than 3/4" of tail rocker choose a longer blank and cut the

excess length from the tail so there is extra foam thickness to shape into. Good shapers plan their

shapes first and choose the best blank for the least amount

of work. In this case we'd cut the tail shorter to where you have

about 1/2" of tail pod thickness and reshape it a little. Chalk it up to

a learning experience, the board will still surf fine and you'll be stoked on

it. |

Sounds like the board won't surf as you had

intended it to. No shame in salvaging the blank and shaping

something different. You can certainly glass on a fin, that's cool too. And you

get a lot of extra glassing experience when glassing on fins. It's a good

thing to do at least once in your board building

life. You could use another longboard blank and 'flip" it so

the nose rocker would be used for the tail (as long

as your outline template fits in the nose

area [which would be the tail of the blank when you flip it]) Some guys flip

the US Blanks 98Y for nose rider

designs. Or we can custom order you a blank to whatever rocker you

want. No problem. |

The EPS sealing paste is used after shaping to

fill in 'tear outs' and provide a nice looking, bright

white surface to glass.

Use stringer

glue or epoxy to glue up the blank. |

We can help you out. No problem. Please schedule a time to bring

your flowboard by the shop to talk about

it. |

Yes, after shaping the foam blank chop off the

end and glue a wood tailblock on. Use masking tape to hold the block

in place. Then

carefully shape the block into the desired tail

shape. |

Glue and clamp pieces of wood together. You can

use wood glue, gorilla glue, or resin. When the tailblock is cured and

you can glue it to the

board. |

Yes just do the calculations based on your board's

thickness in the midpoint, nose, and tail... the goal is to keep the

railbands smooth and flowing so don't get caught up in the numbers too

much. |

| The railband dimensioned layout drawings are found in our free Surfboard Building Guide A-Z |

| Yes, the railbands will taper in the nose and tail areas up to a 1/2" difference from the midpoint dims. It's all relative to the foil of the board. If you are unsure what the railbands will look like simply mark the railband dimensions at the midpoint, 12" from the nose and 12" from the tail and connect the dots with a pencil. Follow the flow of the foil with the line. If the line looks good and matches the flow of the foil then go cut it. If it doesn't look good make a new line until you find what looks right to you. |

Aim for 2 1/2" thick with 4" nose rocker (1/2"

thick at tip) and a 1 1/2" tail rocker (~5/8" thick tail). Foil the

flow of foam to be 2 1/2" thick at the midpoint a bit forward of the

midpoint of the outine. Have fun and feel free to contact us anytime if you have a

question or need anything. |

We certainly do have a lot of customers who make Wakeboards

with our materials. We do custom cuts for wakeboards since there are so many

styles. The blank can be shipped to your door cut in half and you glue

it up for between $35-$50 depending on where you live. Let us know if you have any

questions or would like us to cut you a

blank |

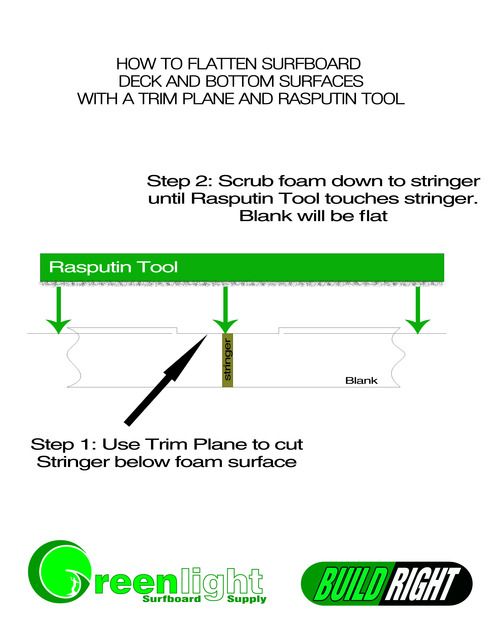

Normally guys use a power

planer to mow down the foam to the thickness you

want. By hand, the trick is to shape the stringer down first with

a trim

plane, then level the foam to the stringer with a G-rasp or shaping

rasp. |

Yes I definitely recommend a spokeshave for fine tuning the stringer and not tearing the foam. But, tear-outs are a common occurance with EPS foam and there is no way around it. There are 2 ways to remedy tear-outs

1. after shaping spread a thin layer of lightweight spackle over the blank to fill in the holes - or you can use an epoxy / Q-cell slurry which gives the board more strength but increases weight a bit.

or

2. Use various sanding screens and foam shaping pad to close up the tear outs. Each progressive sanding screen grit will shave the EPS bead down and not tear. We use up to 320 grit to close them all up...

Please note the quality of the foam has a lot to do with it... make sure the blank in at least 2# density. Also, sharp tools and shaping a little slower help reduce tearouts.

I have used Micro-planes before and in my option they do not take enough foam away. Takes forever to get the shape you want.

We developed PRO-TOOLS to aggressively and efficiently shape EPS foam. They do cause a little tearing which is normal but finishing the shape with spackle or sanding screen makes the board look like a polyurethane blank..

You can find all the Design Guides here: http://

Our surfboard shaping power planer is a great value for a power tool but you can use any planer to skin and shape a blank. Whatever you can find for the lowest cost as long as it has 2 blades. 1 blade will tear the heck out the the foam.

I use a 6" Sawzall blade in my jigsaw to cut the outlines then a railrunner to square it up, or a hard block with sandpaper. (We have plastic Rail Runners for less cost as well)

T12 lights are fine for a shaping room, they put out a bit more light than T8 bulbs. Doesn't really matter, we're looking at shadows on a blank and not necessarily the light.... Position them about 2" above the top of a blank on your shaping racks.

The only feedback we've gotten has been very positive except one guy wore out the grit by trying to shape a stringer which is advised not to do on the site.

The power planer is great for both EPS blanks and PU foam (I've shaped many with this planer) but does not have the on-the-fly depth adjustment of the modified Hitachi.

The adjustment is nice but not necessary to shape a board. With a non-adjusting planer, I usually keep it cutting full depth for the major foam removal and finish the delicate parts in the nose and tail by hand.

Sorry, we don't sell rail band templates. It's almost impossible to have standard rail band templates due to various thicknesses in everyone's foils and length of board. You can make rail band templates to copy boards but not a one-off shape.

Railbands must be shaped according to the board's foil, thickness, and flow as well as the surfer's preference in rail shape.

Laying out railbands is pretty simple. Here are examples of Boxy and Knifey rail bands. Use the chart below to lay out the rail bands you want.

It is best to reshape a SAWZALL blade to fit your jigsaw. Takes a little elbow grease and a file or grinder if you have one. It helps to bend an kink in the tab to help the blade stay in the jigsaw.

Get a 6" one that is wide like this to help keep the cut straight. Any brand will do...

The foil (thickess) of a board is all dependent on the midpoint thickness and volume of foam you need to float.

Most blanks have the foil already shaped in and not much additional tweaking is needed, unless you choose a blank that is not right for the shape.

If you're making a 3" thick board at the middle, the thickness at 12" from the nose and tail will be somewhere in the 1 1/2" to 2" thick range.

There is not right or wrong numbers. It all works.

Here is a reference drawing for the how the rail band dimensions change along the foil of the board that may help you see the proportions of thickness.

You can measure the thickness of your current surfboards as a guide too.

It's simple to shape channels though. Just use a hard block with sandpaper wrapped around it and shape the channels by putting pressure on the corner of the block.

The outline cut is the most crucial aspect to the way your board looks and any dips or wobbles in the outline will show up in the rail and you can't get it out at that point.

For a flawless outline we make a tool called the Rail Runner that does the work for you. It also shapes the bottom tuck of the rail which is one of the most critical aspects of a board since it determines how much "grip" into the wave the board will have so it's best to undershape it to start and screen it to the radius you want. As soon as you cut that tuck railband a little too much the foam is gone and you're intended rail shape is altered.

First, the trim plane is not the best tool for finish passes on the stringer to make it flush with the foam. You want to use a spokeshave for that.

When using the trim plane drag it along the stringer on a 45 degree angle to help keep it flat and not rock sideways which can gauge the foam. Also go along the grain of the wood. You'll know when you're going against the grain because the trim plane will dig in deep an get stuck.

You can also file a radius on the edges of the trim plane blade to keep them from hitting the foam.

This is covered in our Surfboard Building Guide. The calculations based on your board's thickness in the midpoint, nose, and tail... the goal is to keep the railbands smooth and flowing so don't get caught up in the numbers too much.

Here is an illustration on railbands but here it is for reference

Here are suggested rail band dimensions.

The railbands will taper in the nose and tail areas up to a 1/2" difference from the midpoint dims. It's all relative to the foil of the board. If you are unsure what the railbands will look like simply mark the railband dimensions at the midpoint, 12" from the nose and 12" from the tail and connect the dots with a pencil. Follow the flow of the foil with the line. If the line looks good and matches the flow of the foil then go cut it. If it doesn't look good make a new line until you find what looks right to you.

The only difference between the PVC and steel tools is that the steel are heavier and require less "elbow grease" to shape foam as well as come with a lifetime warranty. They both give the same results on the foam.

Normally guys use a power planer to mow down the foam to the thickness you want.

By hand, the trick is to shape the stringer down first with a trim plane, then level the foam to the stringer with a G-rasp or shaping rasp.

If you have all the tools you'll just need a blank, resin, fiberglass, finboxes, and a leash plug to build a board.

We offer surfboard building kits in traditional materials or newer epoxy materials.

You might also want to consider getting just a blank, a beginner glassing kit, and fin boxes of your choice.

We screen EPS with 100 / 150 / 220 / then 320 grit for a super smooth, spackle-free surface. Each screen grit cuts the beads until all the small voids between beads are gone. We use a foam sanding pad with the screen to even out contours. It's more work than spackling but leaves a very nice and clean foam surface.

There are power planers out there specifically designed for surfboard shaping with on-the-fly adjustments for tapering foam(a huge help for shaping rocker, foil, and rails), special dust chutes and handles but any planer will do the job. Just make sure it's got 2 blades so it doesn't tear the foam.

We sell an affordable entry level power planer that does a great job on both PU and EPS foam as well as stringers.While there are no concrete numbers to sufboards it's a good idea when you start to keep more foam in the board that you can fine tune in the end before glassing.

Aim for a 1/2" thick nose tip and a 5/8" tail tip thickness. Then foil your board for a nice flowing line from the nose to tail. Don't get caught up in the numbers too much. Water doesn't know numbers...

Here's more info on Foil from our Design Guide:

SURFBOARD FOIL

The change in thickness you notice when you view aboard from the side is referred to as foil. This thickness flow in most modern boards is smooth and even, without noticeable lumps or transitions. Foil determines to a great degree the overall volume of the board, how it flexes, the degree to which it can be flexed before it snaps, and whether the board is designed for long drivey turns or quick snaps. In general, thinner boards (2 3/8 inches thick or less at the thickest point) will be more flexy, harder to paddle, and less drivey… but more responsive. These boards are most suited for better surf, smaller or more advanced surfers, and strong paddlers. Thicker boards (2 1/2+ inches thick or more at the thickest point) will be less likely to snap but stiffer in terms of flex, will be easier to paddle due to increased buoyancy, and be more drivey. They will be more difficult to control in bigger surf, but work better in weak, small or slow waves because the added volume will allow them to catch waves easier and give the rider something to “push off of” when putting the board on a rail. A thinner board would have a tendency to sink under these conditions. Obviously, heavier and more powerful surfers require boards with more volume for flotation and to resist being pushed too deeply into the water and stalling on a hard turn.

While a trained eye can get a good feel for what the overall thickness flow is doing, and what it is intended for, by viewing from the side, the best way to quantify foil is by taking measurements along the length of the board using calipers. Measurements are most often taken at 12 inches from the nose and tail, 24 inches from the nose and tail, and at the wide point. Typically, boards are 1/8 to 1/4 inch thicker 12 inches from the tail than from the nose, and 1/16 to 1/8 inch thicker 24 inches from the tail than from the nose. The thickest point is typically found at the wide point. Boards designed for drive over responsiveness have their wide points and thick points ahead of center. Retro boards, single fins, classic longboards, and guns are good examples. These boards paddle better because the concentration of foam volume is under the chest when lying prone, and the center of the buoyant force is closer to the front foot when riding. Modern performance shortboards, however, have their wide and thick points behind center, which makes them inherently more difficult to paddle, but have a tighter turning radius. Rather than having the bulk of volume under the chest and front foot, the thick point back puts the concentration of foam between the surfers feet, better facilitating back-footed, rail-to-rail surfing.

It's a good idea to get the stringer flush with the foam so the fiberglass lays flat across the stringer. If it is not flat there will be a gap and there's a good chance the glass will crack there letting water into the board.

Also, a smooth, clean shape is easier to sand. Wavey rails, high and low spots on the deck and bottom will cause a lot more work sanding.

Take your time to get the shape as nice a possible (without overshaping) and you'll find the glassing and sanding process will go pretty smoothly.

The board is foiled from nose to tail so the thickness of the rail is different at 12" from the nose than the midpoint of the board. The rail band chart shows dims for the center of a 2 1/2" thick board. You can measure the thickness of your nose and tail at 12" marks and do a little math to determine the rail marks based on your midpoint rail bands.

After a few boards you can just eye it up though. The most important thing is to keep the rail shape flowing along with the rocker and foil.

Flattening the bottom and deck can be done by hand with two tools: a stringer trim plane and Greenlight Rasputin Tool

Squeeze some Gorilla glue into the gap. It will expand and fill it then you can sand down any excess and glass the board.

Let me preface this reply with the fact that water doesn't know numbers, it's the flow of shape that matters. Numbers are only a guideline to shaping what looks good to our eyes and feels good to our hands.

That being said the railband dimensions change at 12" from the nose and 12" from the tail due to the tapering foil of the blank's profile and the narrower nose and tail widths than the midpoint.

Most importantly you want to copy the bottom rocker onto the side rail and make that taper slightly in the nose and tail areas. The deck rail bands will affect overall volume of the board and shape of the top rail.

You can do math to calculate the rail mark dimensions at the nose and tail based the change in thickness compared to the midpoint. For example, a 2 1/2" thick midpoint rail mark of 1 5/8" [1.63 / 2.5 = ~60% for a 60/40 rail] will reduce down to 1" if the foil thickness is 1 5/8" @ 12" from the nose (~60%)

You can put your rail marks on the board and trace them out (making a tool for that is fine but I use my hand and drag my pinkie along the edge or bottom to trace the outline or rocker and adjust the curve while walking to hit the rail mark dots - or come close.

Then take a look and if you don't like it, make adjustments. It'll all shape off when tools hit the foam.

The apex is between the rail mark and top of tuck and will appear when screening the rail bands to round them off.

Always use the midpoint of the length of your board for the railband measurement, not the widepoint. Although the widepoint being only 4" away will not really affect the railband dimension as the board's thickness should be pretty much the same in that area.

We recommend the most aggressive grit you can get your hands on to shape the foam quicky. We have Tigershark sandpaper which is 36 grit and also our Greenlight shaping rasps are 16 grit and are the most efficient way to shape next to using a power planer.

You can find the rail band designs in the shaping section of our Surfboard Building Guide.

No, you absolutely do not need an electric power planer. We recommend shaping your first few boards by hand with the tools included in the kit to understand what you're doing and have control over how much foam is removed. As soon as you put a power tool between you and the foam there's no telling what mistakes will happen as you're trying to get the hang of both the proper sculpting of foam as well as how to use the planer correctly on foam. Once you shape a board or two by hand and understand the process and how the shape comes along then you can use a planer to take some of the elbow grease out of it...

We do offer customization of your blank to take away most of the useless power planing to thickness. If you'd like we can provide your blank 1/4" thicker than your final shape thickness so you only have to scrub a total of 1/4" of foam (1/8" from deck and bottom) which is pretty quick with out rasps provided in the kit. If you want a custom blank thickness just put a note in the "custom blank specifications" section of the cart and we'll cut it the that thickness. No problem.

No, you absolutely do not need an electric power planer. We recommend shaping your first few boards by hand with the tools included in the kit to understand what you're doing and have control over how much foam is removed. As soon as you put a power tool between you and the foam there's no telling what mistakes will happen as you're trying to get the hang of both the proper sculpting of foam as well as how to use the planer correctly on foam. Once you shape a board or two by hand and understand the process and how the shape comes along then you can use a planer to take some of the elbow grease out of it...

We do offer customization of your blank to take away most of the useless power planing to thickness. If you'd like we can provide your blank 1/4" thicker than your final shape thickness so you only have to scrub a total of 1/4" of foam (1/8" from deck and bottom) which is pretty quick with out rasps provided in the kit. If you want a custom blank thickness just put a note in the "custom blank specifications" section of the cart and we'll cut it the that thickness. No problem.

| The easiest fin box system to install for the side bite would be the Factory fin plugs, or FCS X-2 plugs. You can also buy inexpensive quick set jigs and FCS T-3 Holesaw to install the plugs. |

| CLICK HERE for the FCS X-2 Fin Plug Install Manual More detailed install info below: NOTE: For EPS boards use Slow Hardener Epoxy or set the plugs with 2 resin pours to reduce exotherm and prevent melting the foam. See Step 4. 1. FCS X-2 and FACTORY plugs are installed after the seal coat. After installation and the resin has cured, you sand them down flush with the board while sanding the bottom. 2. Once you have the quickset jigs laid out on the board (lined up with your shapers dots) you will use a FCS Hole Saw bit or FACTORY Holesaw to make your holes for the plugs. Drill the hole 5/8" deep and pull the foam out with needle nose pliers or dig out with a flathead screwdriver. 3. We suggest using either FCS dummy jigs or a set of fins to set the plugs with the correct spacing as well as adjust the fin cant angle. Lightly screw the plugs onto the dummy jig tabs. If using fin keep the plugs loose on the fin tabs so you can push them down to where the "nubs" on the plugs touch the seal coat. 4. Polyester boards: Mix 1 oz of resin per plug. (6 oz total for a tri-fin, 8 oz total for a quad). EPS boards: Use Slow Cure epoxy resin, or if using Fast cure, mix 1/2 oz resin per plug. Pour resin in the holes about 1/3rd deep to set the plugs in. You will come back and fill the rest of the perimeter in another step. Doing 2 separate pours will prevent the EPS foam from potentially melting from epoxy exotherm. 5. Polyester Board: Pour about 1/2 oz of mixed resin into the holes. EPS Board: Pour about 1/2 oz mixed resin into the holes. 6. Place the plugs in the holes with the dummy jig or fins to ensure proper alignment. Set the fin cant to the desired angle and hold in place with tape. Here is an illustration of taping the fins in place (these are glass ons but same taping methods apply to FCS fin plugs)

7. Polyester Boards: Using a small cup (dixie cups work great) carefully pour resin around the perimeter of the plug so it runs into the drilled hole. Be careful not to over fill! Fill just under the lip of the plug and jig. EPS Boards: Let the first pour cure for about 2 hours then mix another 1/2 oz epoxy resin per plug and top off. Once the resin cures remove the jigs and sand the plugs down until they are flush with the board. |

| Yes, the front dummy fin cant is 6.5 degrees, the rears and sitebite fins are 4 and 3 degree, respectively. |

½ oz per X-2 plug, mix ½ cc MEKP per ½ oz

polyester resin: so for a tri fin (6 X-2 plugs) mix 3 oz

poly resin and 1.5 cc

catalyst You can download our resin chart HERE

which includes info on how much resin to use for

finboxes |

Glass the fins on after laminating the board and

before hotcoating. You'll hotcoat the board and fins

all at the same time.

Watch this video to

learn how to glass on fins. |

| Check out Greenlight's Fin Position Layout Guide HERE |

FCS

Fusion fin boxes were invented because of the growing popularity of

EPS/Epoxy construction. Not to say you can't use

the traditional X-2

plugs but it's a longer process. You need to pour a little epoxy in the hole

to set the plugs, then a few hours later you finish off with more resin. A 2 part pour reduces

exotherm which melts the EPS causing a weak install. It's a

must to use Resin

Research Quik Kick resin for plugs for less exotherm. You can also

put cold icepacks under the fin area while installing

to reduce exotherm. In our opinion FCS

Fusions are better overall for ease of install and

strength. |

| Yes you can use the same resin for glass on the

fins. Nothing special is

required. Glass

on fin roving can be purchased HERE |

White pigment is available HERE,

you can use this with any resin but whenever you use UV

cure resin you need to add MEKP

to colorwork and finboxes to ensure it all cures. |

Take a small drill (around 1/16" diameter) and

carefully drill out the cured resin until a fin key can fit. Then back

the screw out, it will

pull the rest of the resin out with it. Take your time and make sure not to

hit the finbox threads with the drillbit. |

Drill the plug out with a holesaw

and a template

to drill out the remaining parts of the plug and resin. Might need

to pull it out with

plyers. Fill hole 1/2 way with resin and cab-o-sil.

Slide your fin tab into the new plug (do not screw) and drop it into the hole while sliding other

tab into existing 2nd plug for alignment. Push

the plug down until the tabs touch the

glass. The jig will act as a resin dam, fill in the rest of the hole

with resin being careful

not to overfill and get the screw submerged in resin. When cured remove fin

and template, screw down the screw, and

sand the plug and resin flush with the board. For

additional strength you can

laminate a patch of 4 oz. fiberglass over the plug, hotcoat and sand. Good as

new. |

Yes, you

need a special install jig for the longboard fin boxes. Here's a link to the

jig. Same router for all fin systems and longboard

fin boxes. |

All fin boxes are ordered as a single box... so you'll order (2) 9 degree, (2) 5 degree, (2) 3 degree, and (1) 0 degree [center box]