Understanding Epoxy Resin Crystallization and How to Re-Liquify It

Epoxy resin is a versatile material used in various industries, from surfboards, to construction, to crafts. However, one common issue users encounter is crystallization. Understanding how and why epoxy resin crystallizes, the temperatures at which this occurs, and how to effectively re-liquify the resin can help maintain its usability and extend its shelf life. This blog post will delve into the science behind epoxy resin crystallization and provide practical methods to restore crystallized resin to it's liquid state.

What is Epoxy Resin Crystallization?

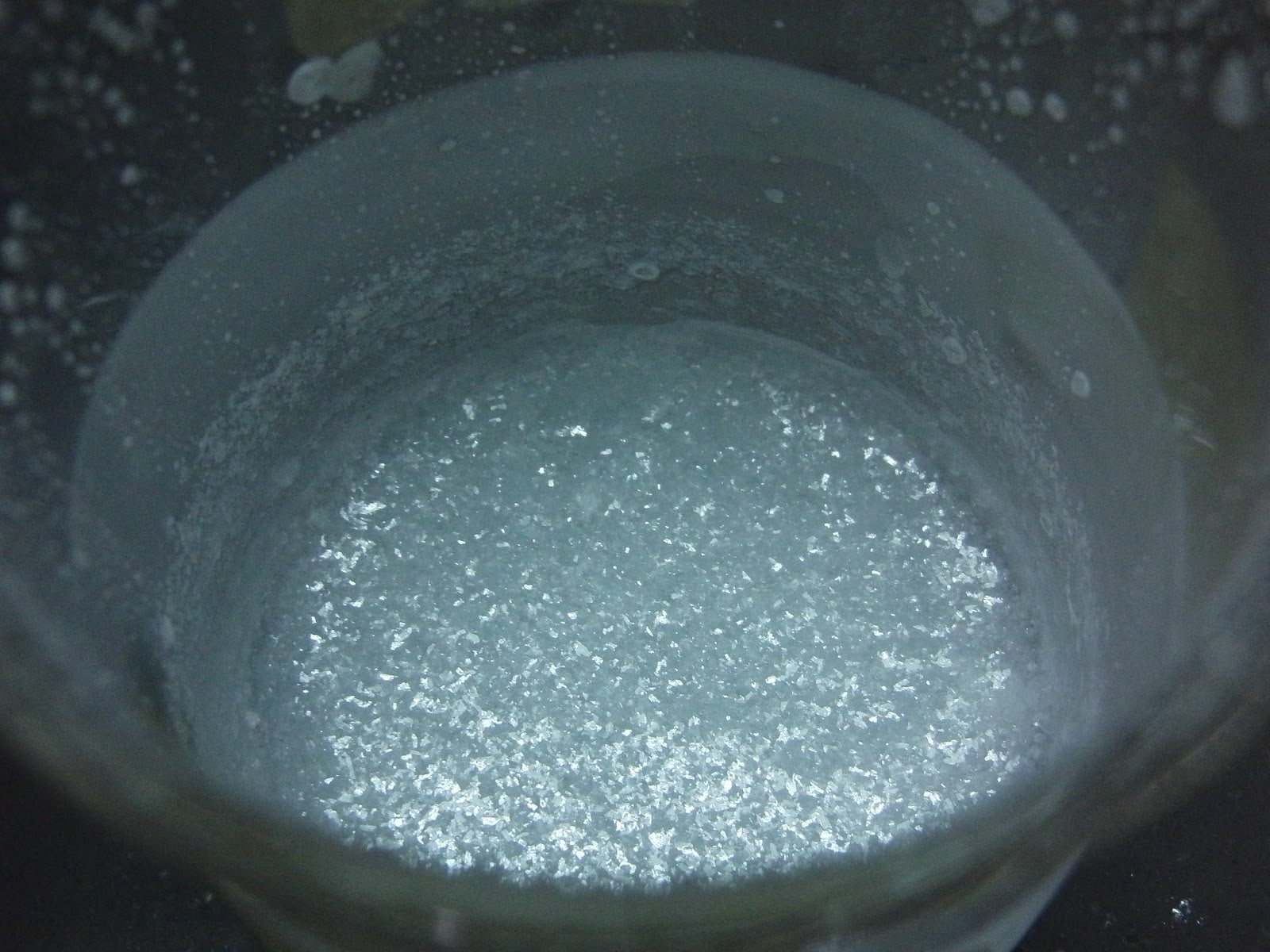

Epoxy resin crystallization is a physical change where the resin transforms from a liquid to a semi-solid or solid crystalline state. This process can occur due to various factors, including temperature fluctuations and prolonged storage. When epoxy resin crystallizes, it can become challenging to work with, as its viscosity increases, making it difficult to pour, mix, and apply.

Why Does Epoxy Resin Crystallize?

Several factors contribute to the crystallization of epoxy resin:

-

Temperature Fluctuations: The most significant factor in epoxy resin crystallization is temperature change. When the resin is exposed to temperatures below its ideal storage range, it can start to crystallize. Cold temperatures slow down the molecular movement in the resin, causing the molecules to arrange themselves into a crystalline structure.

-

Prolonged Storage: Over time, epoxy resin can naturally tend to crystallize, especially if stored for extended periods. Even under ideal conditions, the resin's molecules can slowly arrange into a crystalline structure.

-

Repeated Heating and Cooling Cycles: When epoxy resin is subjected to repeated cycles of heating and cooling, it can lead to crystallization. Each cycle increases the likelihood of the molecules arranging into a crystalline pattern.

At What Temperatures Does Epoxy Resin Crystallize?

Epoxy resin can begin to crystallize at temperatures around 60°F (16°C). However, the crystallization process accelerates at lower temperatures, becoming more pronounced as temperatures approach freezing. It's crucial to note that different epoxy resin formulations have varying crystallization points. Therefore, always refer to the manufacturer's recommendations for specific storage temperatures to minimize the risk of crystallization.

Methods to Re-Liquify Crystallized Epoxy Resin

If you find that your epoxy resin has crystallized, don't worry. You can re-liquify it and restore its usability through several methods. The primary goal is to apply gentle, consistent heat to break down the crystalline structure without overheating the resin, which could degrade its quality. Here are some effective methods:

-

Hot Water Bath: One of the simplest and most effective methods to re-liquify epoxy resin is using a hot water bath. Here’s how to do it:

- Step 1: Fill a container or sink with hot water (not boiling). The water should be around 120°F to 140°F (49°C to 60°C).

- Step 2: Place the sealed epoxy resin container into the hot water bath. Ensure the water level is below the lid to prevent water from entering the resin.

- Step 3: Allow the resin to sit in the hot water for 15-30 minutes. Occasionally shake or stir the resin container to help distribute the heat evenly.

- Step 4: Check the resin’s consistency. If it has returned to a liquid state, remove it from the water bath and dry the container thoroughly before opening. There may still be a "slug" of crystalized resin in the center of you bottle. The the heat did not get to. Just pour and mix the liquid part and re-heat the remaining epoxy resin slug for the next use.

-

Heat Gun or Hair Dryer: If you need a quicker method, you can use a heat gun or hair dryer to apply direct heat to the resin container. This method requires more attention to avoid overheating.

- Step 1: Set the heat gun or hair dryer to a low or medium heat setting.

- Step 2: Hold the heat source 6-12 inches away from the resin container.

- Step 3: Move the heat source in a circular motion around the container to distribute the heat evenly.

- Step 4: Continue heating until the resin returns to a liquid state. Shake or stir the container periodically to ensure even heating.

-

Microwave Oven: For larger quantities of crystallized epoxy resin, a microwave oven can be used. This method requires careful attention to avoid overheating.

- Step 1: Place the epoxy resin container in the microwave. Make sure the lid is tight if you have to lay the container on it's side.

- Step 2: Microwave the resin on a low power setting for no longer than 1 minute.

- Step 3: Check the resin's consistency. If it has not fully re-liquified, continue microwaving in short bursts of 15-30 seconds, shaking the constainer between each burst.

- Step 4: Once the resin is fully re-liquified, remove it from the microwave and allow it to cool to room temperature before using.

Special note: I used to glass boards in an unheated warehouse where temperatures dropped to 35 degrees in the winter. I did not have a warm area to store resin so I regularly used the microwave trick to re-liquify the resin. Worked every time. See the video below. Also see this blog post about thermal shock when glassing with warm resin in a cold workspace...

-

Warm Storage Area: If you are not in a hurry, you can place the crystallized resin in a warm storage area, such as near a heater or in a warm room. This method takes longer but requires less active monitoring.

- Step 1: Find a warm storage area with a consistent temperature between 70°F and 85°F (21°C to 29°C).

- Step 2: Place the sealed resin container in the warm area.

- Step 3: Leave the resin undisturbed for several days, occasionally shaking or stirring to help break down the crystals.

- Step 4: Check the resin periodically until it has returned to a liquid state.

Important Considerations

When re-liquifying crystallized epoxy resin, it's essential to keep the following considerations in mind:

-

Avoid Overheating: Overheating the resin can degrade its quality, affecting its performance and curing properties. Always use the lowest effective heat setting and monitor the resin closely during the re-liquification process.

-

Seal the Container: Ensure the resin container is tightly sealed during the re-liquification process to prevent moisture from entering. Moisture can cause further crystallization or affect the resin’s curing properties.

-

Uniform Heating: Apply heat evenly to avoid hot spots, which can degrade the resin. Shaking or stirring the resin container helps distribute the heat uniformly.

-

Monitor Temperature: Use a thermometer to monitor the temperature of the water bath, oven, or storage area to ensure it remains within the recommended range.

-

Check Manufacturer Guidelines: Always refer to the manufacturer’s guidelines for specific instructions on handling and re-liquifying crystallized resin. Different formulations may have unique requirements.

Preventing Future Crystallization

To minimize the risk of epoxy resin crystallizing again, consider the following preventive measures:

-

Proper Storage: Store epoxy resin in a controlled environment with a consistent temperature between 60°F and 80°F (15°C and 27°C). Avoid storing resin in areas prone to temperature fluctuations, such as garages or outdoor sheds.

-

Airtight Containers: Use airtight containers to store epoxy resin to prevent moisture and impurities from entering. Ensure the container lid is tightly sealed after each use.

-

Desiccants: Consider adding desiccant packs to the resin container to absorb any moisture that might enter. This can help maintain the resin’s quality and reduce the risk of crystallization.

-

Rotate Stock: If you have multiple containers of epoxy resin, rotate your stock to ensure older resin is used first. This practice helps prevent prolonged storage and reduces the likelihood of crystallization.

-

Avoid Repeated Heating and Cooling: Minimize the number of times the resin is exposed to heating and cooling cycles. Only heat the resin when necessary and avoid leaving it in cold environments.

Conclusion

Epoxy resin crystallization is a common issue that can be effectively managed with proper understanding and techniques. By recognizing the factors that contribute to crystallization and implementing methods to re-liquify the resin, you can maintain its usability and extend its shelf life. Remember to store your epoxy resin in a controlled environment, and follow manufacturer guidelines to prevent future crystallization. With these practices, you can ensure your epoxy resin remains in optimal condition and easy to use for all your projects.