News

RSS-

When building a surfboard, one of the most critical decisions you'll make is choosing the right resin. Resin is what binds the fiberglass cloth to the surfboard, giving it strength, durability, and a glossy finish. There are several types of resins used in the industry, each with its unique properties and benefits. In this guide, we'll explore the two most common types of surfboard resins: polyester and epoxy, with a focus on how they impact the performance and longevity of your surfboard.Read now

When building a surfboard, one of the most critical decisions you'll make is choosing the right resin. Resin is what binds the fiberglass cloth to the surfboard, giving it strength, durability, and a glossy finish. There are several types of resins used in the industry, each with its unique properties and benefits. In this guide, we'll explore the two most common types of surfboard resins: polyester and epoxy, with a focus on how they impact the performance and longevity of your surfboard.Read now -

Understanding Epoxy Drying vs. Curing Times: A Comprehensive Guide

When working with Greenlight Marine Grade epoxy resin, distinguishing between drying and curing times is crucial for ensuring the quality and durability of your projects. This guide will delve into the intricacies of these processes, how temperature affects them, and specific drying times based on the hardener used.Read now -

Understanding Thermal Shock When Fiberglassing Surfboards

Fiberglassing surfboards involves applying a resin (a type of liquid plastic) to the surfboard to make it strong and smooth. However, if the resin and the surfboard blank (the foam core of the surfboard) are at different temperatures, it can cause thermal shock, leading to problems like uneven curing, orange peel texture, cracks, and air bubbles. Let's explore what thermal shock is, how it happens, and how to avoid it.Read now -

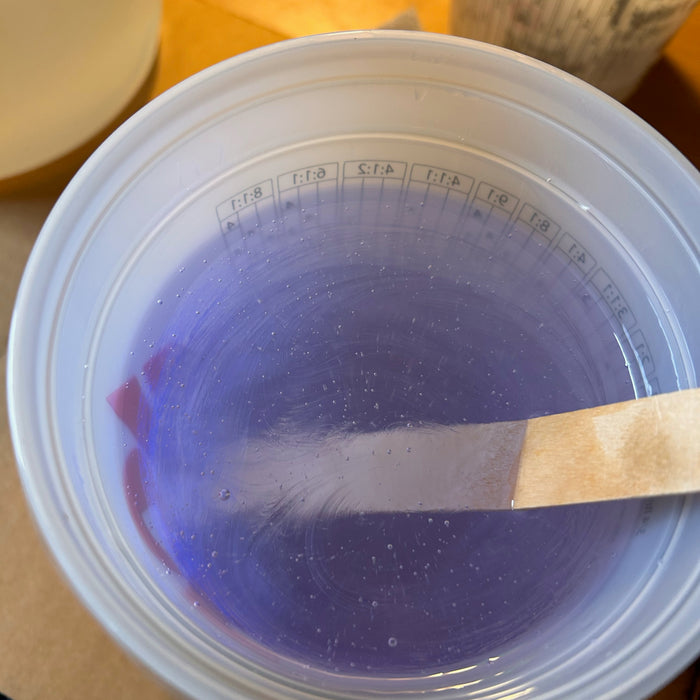

Understanding Epoxy Resin Crystallization and How to Re-Liquify It

Epoxy resin is a versatile material used in various industries, from surfboards, to construction, to crafts. However, one common issue users encounter is crystallization. Understanding how and why epoxy resin crystallizes, the temperatures at which this occurs, and how to effectively re-liquify the resin can help maintain its usability and extend its shelf life. This blog post will delve into the science behind epoxy resin crystallization and provide practical methods to restore crystallized resin to it's liquid state.Read now -

How Long to Wait for Resin to Cure Before Pulling Tape or Cutting the Lap

Read nowSince temperatures fluctuate and resin pot life varies with volume the rule of thumb when it comes to pulling tape cut laps is to touch a bead of resin on the tape with your finger. If it sticks to your...

-

Fiberglassing with Epoxy Resin in Cold Winter Temps

Read nowHere are a few tips for fiberglassing with epoxy resin in the winter time when the temperatures are colder than you'd like... Epoxy resin is temperature sensitive and its viscosity will thicken in cold as well as cure slower. Conversely,...

-

How to eliminate fish eyes and pin holes in epoxy coatings

Read nowHow to eliminate fish eyes and pin holes in epoxy coatings Fisheyes and pin holes are dips, separations, or irregularities in an otherwise flat epoxy coating. What causes fish eyes and pin holes in epoxy? Substrate contamination is the most...

-

Greenlight's Surfboard Building Philosophies #10 Trouble Free Epoxy Glassing Tips

Read nowIt looks like glassing your boards with epoxy resin has become the more popular choice over polyester resin based on our records this year. Years ago we had plenty of experienced poly guys come into the shop stating they’ll never...