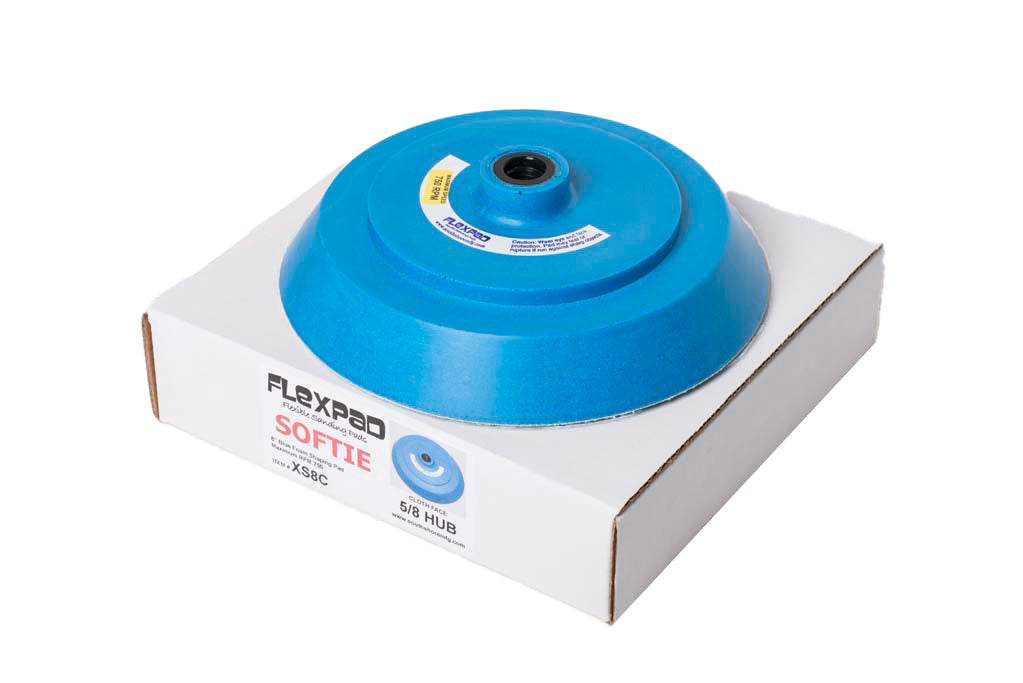

Flexpad Surfboard Sanding Pads 8" Diameter

Flexpad 8" Sanding Pads

FLEXPADS sanding pads are used on power sander/polishers with a 5/8-11 male thread. Designed primarily to be used for sanding Surfboards they are also used in the Auto Body, Marine and Woodworking industries.

Flexpads are constructed using multiple foam pad densities and are made in two sanding pad sizes 6" and 8" for all your sanding needs.

All Flexpad sanding pads are cloth backed for use with 8" Peel and Stick Sandpaper Discs or cut your own discs with cloth backed sandpaper and adhere them to the sanding pads with a light coating of spray adhesive.

SOFTIE DENSITY - This Flexpad was created specifically for SHAPING surfboards, the foam sanding pad is extremely soft and consistent making it useful in many shaping situations.

These sanding pads rarely if ever go out of true, should last you a lifetime! Fits any 5/8 X 11 pitch coarse-male thread arbor. Maximum RPM: 750

SOFT DENSITY - This Flexpad was made specifically for building surfboards, the pad is excellent to sand curves, rounds, and concaves without swirls. These sanding pads rarely if ever go out of true, should last you a lifetime! Fits any 5/8 X 11 pitch coarse-male thread arbor. Maximum RPM: 1750

MEDIUM DENSITY - This Flexpad was made specifically for building surfboards, the medium SurfPad is a great all-around sanding pad. It's medium density will sand swirl free and still give that excellent edge to feather with. Flexpads rarely if ever go out of true, should last you a lifetime! Fits any 5/8 X 11 pitch coarse-male thread arbor. Maximum RPM: 2800

HARD DENSITY - This Flexpad was made specifically for building surfboards, the Hard SurfPad is a great sanding pad for taking down flats or large bumps. It's hard density will sand swirl free and still give that excellent edge to feather with. These sanding pads rarely if ever go out of true, should last you a lifetime! Fits any 5/8 X 11 pitch coarse-male thread arbor. Maximum RPM: 5000

Different Sanding Pad Densities for Different Projects

The purpose of the different sanding pad densities is to be able to get the scratches and flatten out whatever you are sanding. By starting with the hard pad and working your way down to the soft sanding pad, with correct grits of sandpaper, you can eliminate all bumps and ridges from the resin. To get the finished look that the professional level sanders create, you are looking at using 2 to 3 pads to finish your work.

Flexpads are manufactured for years of service. Exceeding the recommended top RPM may cause pad failure and void any warranty.